It is up to you on whether or not to hire out a contractor for your Starlink system. I'm thinking that most people are going to try and tackle this themselves in order to try and save some money...well possibly save some money. If this is not done right, or a mistake happens along the way the outcome could be that you'll end up paying more than if you would've hired a professional. That being said this isn't rocket science, so it really shouldn't be that hard. There are just some key details that if followed will make your installation be top notch. We're going to break this down into categories and over a few posts, so if you're looking for another installation tip then try using our search engine to find more.

DRILLING THROUGH A WALL

There is such a wide variety of homes using varying materials that there really isn't a one answer fits all. That being said, we're going to cover some of the more well known materials that have been used, will go through and list helpful tools and tips to help make your installation as easy as possible.

The Tools.

A good drill and long sharp drill bits 1 inch diameter recommended, sealant, tuck-tape...

A decent drill, one with a hammer function really helps if you're going through Stucco or small amounts of concrete and brick. If you're trying to penetrate through a concrete foundation then you'll need a large hammer drill, they can be rented for fairly cheap and make a huge difference.

Generally you're not going to be drilling through the foundation but we have seen a material in modern homes called block forming in which the walls have a thick concrete core where a regular drill will not work, you'll need one of these larger drills to get through thick concrete. Sealing is extremely important here, a proper seal will prevent rot, mold and little critters and bugs from gaining access into your home. make sure you have good sealing products to help.

Scouting your property.

As an installer for 20 years I've drilled a lot of holes. When you're out in the rural area you don't always have a hardware store close by, so you learn to improvise and work smartly. Take your time and get measurements, the old carpenter rule is "measure twice cut once". Depending on what generation Starlink system you have, your cable may have 75ft,100Ft and 150Ft cable lengths to work with. This will factor into where you'll be able to place the cable run. I'm usually eyeing up the corners, where the line runs straight down the seam looking very inconspicuous. If you have vinyl siding then you could look at running the cable in behind. be careful with this as you need the right tools to snap the siding in and out. If the siding is older then I wouldn't advise pulling it off as it rarely goes back the same way and you'll end up fighting with it to get it just right. The other option is you might be able to go through the attic dropping the cable down, this is a good option but be prepared to suit up, as you'll be working in insulation. Dress up covering all exposed skin and wear a mask, if you're fortunate to have enough room to maneuver around without disrupting the installation then this certainly makes it more appealing. Will cover attic work in another article.

How's your home built?

Once you've identified the material you're drilling through, you need to make sure you have a drill bit long enough. The drill bit needs to have extra length to compensate for the piece that is in the drill chuck, minimum 2 inches but hopefully more. Example: Your wall is 14 inches thick you'll need a minimum 16 inch bit. The material you're cutting through will tell you what kind of bit you'll need. Don't use a spade wood bit to cut through stucco, although you might get it through you'll damage the bit and create a messy cut. Use the right bit for the job. Stucco, especially older stucco will need a masonry bit in order to cut through it.

Drilling through a wall, you need to map out as much area around, above and below, looking for electrical outlets or old wall plates, something you can use as a marker. Look inside and outside, sometimes conduits can be run on outside walls. I usually like to head right to the basement utility room, if you're lucky you will find some open ceiling in the basement where you can map out how electrical, water and gas lines are run. You can usually find a great place to enter a home as the gas/water and electrical lines exit the home here. The lines are usually fed just above the foundation and usually come into the furnace/breaker panel room. you can find the older tv cables and telephone lines as well. These won't be any use to you for Starlink but sometimes they can be used for tracking and fishing for your cable run. If you have a modern home with Cat5E cabling then you could possibly tie into that cabling, this can really save you a lot of time and give you a robust professional home network, hardwired speeds are always better and more consistent. Follow where the gas, water, electrical lines are going to the outside, you can tell from here how high up the foundation has been poured and if you can come in beside these lines, it makes for an easy entrance into your home. (If your basement is completely finished or the utility room is central then this will be more difficult to feed too. I would use a long thin pole(Fish Pole), remove the conduit covers and see if there is enough room in one of them to push your pole through and see if it can stretch all the way to the utility room. If it goes through with ease then this is an option, jobs like this are better with 2 people, as one can be inside while the other is outside to help pull the cable through.

With so many options for bringing the cable in, you have to plan out where the best entrance will be. Placing the router in a central area, covering as much of your home is ideal but not always the most practical. If you have already been using the Starlink system(Which I highly recommend) then you already have a good idea of its range capabilities. Homes around 2000 sq ft can easily be covered by the factory router with proper placement.

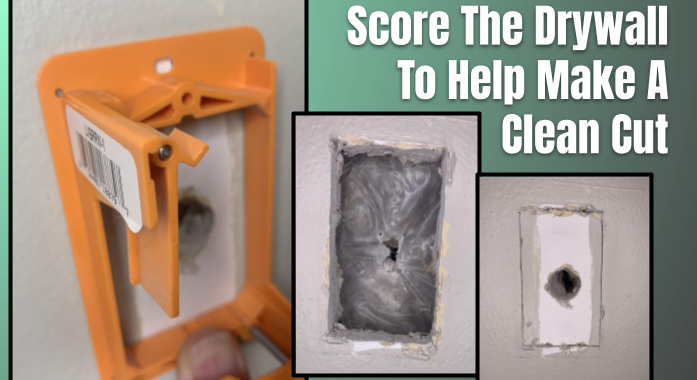

So we've weighed out the options and have decided to drill through an upper floor wall where there was an old line. Before drilling, mark out all areas and use a stud finder that has the ability to detect electrical current to make sure you're not going to hit any power lines or going straight through a stud(Beside a stud is ideal). If you see an outlet on either side of your selected location then there is a chance that a cable could be linking the two together. If you don't have a stud/current finder then take your time, being extra careful not to cause any damage. So we've looked at both the inside and outside and it looks clear, let's go inside and start cutting. If you're planning on putting up a wall plate to make it look pro then place your box on the wall and cut out the inside diameter using a drywall-knife, once you have the drywall piece cut out you will see a thin plastic barrier, this is known as a vapor barrier. This is used to prevent water from being able to get into your wall which can lead to mold and rot. You're going to want to make sure to seal this back up as much as possible. Use your knife, put a slit down the center big enough to get your 1' drill bit through. Behind the vapor barrier is insulation. Take your drill bit with just your hand, using the chuck side of the bit (not the cutting side) and push into the insulation while moving it in a small circular motions, this is separating up the insulation well checking for any other cables or water lines that could be in there, hence the reason you use your hand for this. The purpose of doing this is to prevent the insulation from getting caught and twisting around the bit while drilling. The insulation will try to get back to its original shape so this must be done somewhat quickly. Once you have opened the insulation around the bit, place it into your drill and insert it through the opening till you feel the tip hitting on the outside wall. Slowly begin drilling and watch for any catching insulation. If it starts to catch then go back a step and clear it out. If it turns without catching any insulation then slowly pick up the speed of the bit while applying moderate pressure. I say moderate pressure for a reason, a sharp bit will cut easily and produce a much cleaner finish, a dull bit requires a lot of pressure possibly causing a blow-out at the end from all the pressure being used. I've seen lots of cracked siding and large stucco pieces from installers using dull tools with too much pressure. You should be able to feel the bit cutting through the wood, as it gets to the siding you will feel it get a bit springy, like it is pushing back. Lighten up on the pressure and just use the bit for cutting with minimal pressure. This will help to cut a nice clean circular hole on the outside. You will feel it pop out as the siding gives way. If you're going through stucco or brick then make sure you're using a concrete bit and place your drill on hammer mode. You have to put moderate pressure when cutting through these materials but don't be over aggressive, let the bit do the work for you. Once you've popped through, check the outside hole for burs or any sharp objects that could damage your line and remove them.

You managed to get a nice clean cut 1" hole through your wall, congratulations! Now we need to get the Starlink cable through it. Depending on the depth of the hole you might be able to just push the cable through, but make sure to tape it up, covering the connections. You can do a lot of damage to the connection by shoving it into a fiberglass and wood chipped filled hole, tape it up covering up all parts of the connection. If needed attach your cable using the tape to your fish to help feed it through deeper holes. Pull the cable through the hole with the extra slack being brought inside or left up at the dish. Quick note here for running outside lines horizontally, place clips a minimum 2ft apart to prevent cable sagging, this will help the cable to stay in place making it look professional over time.

Head outside to seal up your hole, place a drip loop on your exterior line. This will be a 6-8 inch loop that dips just below the entrance hole. This will help prevent extra water from penetrating the hole by dripping off of the bottom of the loop. You won't be able to prevent all water but every little bit will help the hole to stay sealed for a long time to come. Install your sealing product while the line is loose to help plug the inside of the hole. Once the drip loop is installed then reapply more sealant all around the hole, making sure that every little bit is sealed. If you're working with brick or stucco then make sure you're pre-drilling your clamping holes, using the lowest speed as well, maybe even hand-tightening the clamps to prevent twisting your cable and damaging it.

Head back inside, take your tuck tape and place it around the sliced vapor barrier and cable line to help seal the inside. Place the cable through the wall plate box and cover plate and install. These plastic boxes come in a variety of styles so make sure to follow the instructions for yours properly. All the parts we used today we're found in our local hardware store. Well you've done it, made a plan and managed to install your cable just how you hoped. The Dishy cable has been brought through a wall and is working top notch while looking professional.

There are many other styles of home that we've come across, log homes, straw-bail, metal... are all out there, although these homes are less common. Each one needs to be handled differently, make sure to consult with a pro if you have any doubt at all. Most professionals will at least guide you in the right direction, and give you a free quote so you know just how much it would cost to get it done by them. We hope you have enjoyed this article, please become a member to stay up to date with everything Starlink.

Comentarios